Compact, quiet, efficient – the SCHOTTEL PumpJet has stood the test of time as a reliable take-home system as well as manoeuvring and main propulsion system in all types of vessels where maximum manoeuvring performance, space-saving installation and utmost comfort are paramount. As a modern shallow-water propulsion unit, the SPJ provides full thrust in all directions even at minimum immersion depths. The flush installation along the vessel’s hull provides optimal protection against damage in the event of ground contact and is supplemented by an inlet grid.

The extremely compact design enables space-saving installation with minimal displacement losses. Since the SCHOTTEL PumpJet is installed flush with the vessel’s hull, this not only minimizes the ship resistance, but the risk of damage is also reduced considerably. This makes the robust SPJ the perfect choice for operation in extremely shallow waters.

Furthermore, the SPJ guarantees low noise and vibration levels. It is therefore ideal for ships with high comfort requirements, such as passenger ships and yachts. The propulsion unit is optionally available with a resilient mount, which further reduces noise levels and vibrations.

| Type | Input power [kW] | SPJ Ø [m] | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SPJ 15 | 50 | 55 | 60 | 75 | 0.66 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SPJ 22 | 72 | 80 | 90 | 110 | 0.90 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SPJ 30 | 90 | 100 | 105 | 120 | 150 | 1.00 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SPJ 57 | 150 | 170 | 185 | 210 | 257 | 1.30 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SPJ 82 | 250 | 280 | 300 | 350 | 420 | 1.68 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SPJ 132 | 450 | 490 | 530 | 610 | 746 | 2.18 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SPJ 180 | 600 | 660 | 720 | 850 | 1000 | 2.70 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SPJ 220 | 750 | 820 | 900 | 1050 | 1250 | 2.70 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SPJ 320 | 1300 | 1450 | 1600 | 1850 | 2200 | 3.40 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SPJ 520 | 2100 | 2300 | 2500 | 3000 | 3500 | 4.30 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

S = Standard, O = Option The above information is for guidance only. They do not apply to ice-classified ships. The final choice of propulsion unit depends on the actual operational profile of the vessel and is determined by SCHOTTEL. The ratings given are based on experience in the typical areas of operation of the respective vessel types. If you cannot identify your application in the “Typical applications” section or if you have a vessel with a special area of application, SCHOTTEL will be happy to determine the most suitable propulsion unit for you.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

In addition to developing new products and services, SCHOTTEL works continuously to optimize existing systems. Special features ensure that customers worldwide benefit from state-of-the-art solutions.

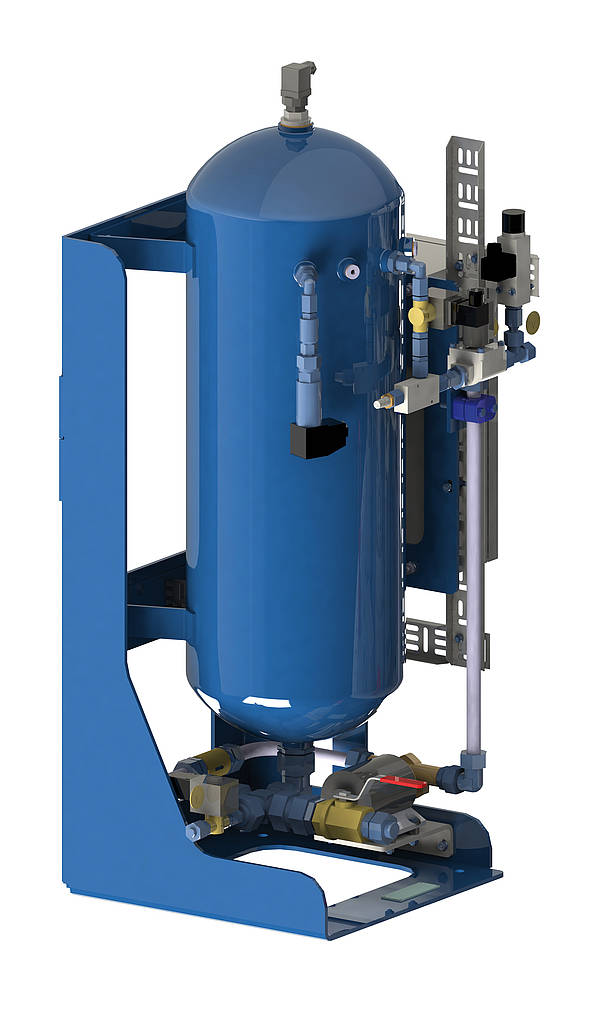

SCHOTTEL LeaCon is a sealing system certified by DNV which offers safe and reliable protection against contamination of the seawater by operating materials. Separate seals to the seawater and to the gearbox side ensure that both incoming seawater and escaping gear oil are collected in an intermediate chamber (LeaCon chamber). This effectively prevents water from entering the gearbox and, above all, oil from escaping into the seawater. With the connected vacuum system, the leakage fluid is automatically collected in a compact tank in the engine room.

In addition to the leakage-free sealing against seawater, the LeaCon system is used to monitor the condition of the seals. It registers the amount of leakage collected and continuously checks the condition of the seals. This means that operational wear can be detected at an early stage and unscheduled maintenance can be avoided.

SCHOTTEL propulsion units equipped with the LeaCon sealing system comply with the VGP regulations of the US-American Environmental Protection Agency (EPA). There is no need to use bio oils (EAL).

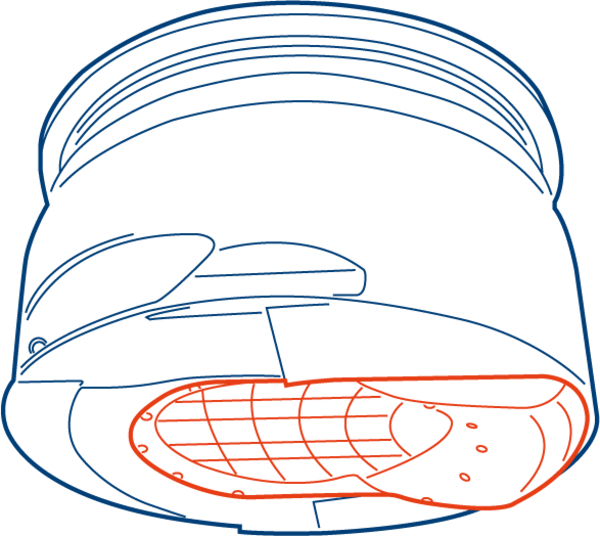

The proven SCHOTTEL PumpJet is available now with an optional new feature: the SCHOTTEL CoaGrid. This takes advantage of the Coandă effect, i.e. a liquid’s tendency to “run along” a convex surface. A new streamlined geometry has been developed on the underside of the pump jet housing using in-house CFD enhancements. This allows the water flow to be directed more effectively into the pump jet inlet. This means higher propulsion efficiency and lower noise levels.

An installation variant with elastic mount is available for the pump jet. This is characterized by a particularly low noise and vibration level, which increases passenger comfort enormously. In addition, the elastic mount helps to minimize underwater noise.

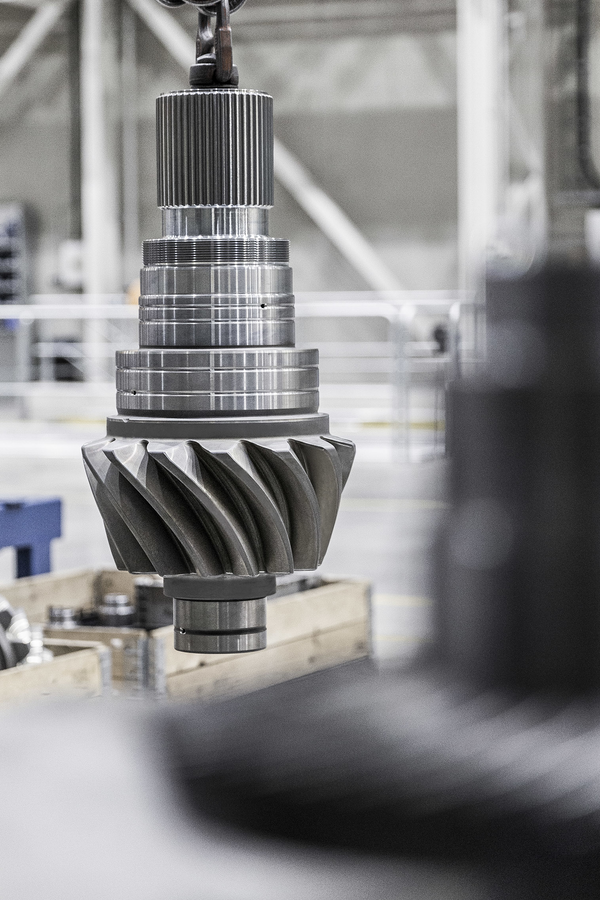

SCHOTTEL’s self-developed High Torque Gear (HTG) extends the service life of the gearbox, resulting in significant performance and safety gains. State-of-the-art milling and calculation methods are used to achieve shapes that enable a highly efficient, robust and safe gearbox with ideal gear geometry.

The HTG allows for example up to 15 percent more drive torque to be applied with the same bevel gear dimensions and in compliance with the same safety requirements of the classification societies.