Powerful, reliable, flexible – the SCHOTTEL Retractable RudderPropeller is the retractable version of the proven SCHOTTEL RudderPropeller. When retracted, the SRP-R functions as a fully 360-degree steerable propulsion unit. It combines maximum manoeuvrability, high propulsion power and precise dynamic positioning. The retractable thruster can also be equipped with an eight degrees inclined propeller shaft. This reduces the interactions between the propulsion units as well as between the units and the hull, resulting in even more propulsion efficiency.

The SRP is subject to continuous development to ensure that the latest technology is always available. Today, the rudder propeller is available in numerous variants covering a wide range of power sources or installation options. This great variety makes the SCHOTTEL RudderPropeller extremely versatile and able to meet special requirements.

Developed and built in 1950 by Josef Becker, the founder of today’s SCHOTTEL Group, he quickly gained a foothold in the world of modern shipbuilding. The main distinguishing feature of the SRP is the combination of propulsion unit and azimuth steering. This makes a rudder superfluous and converts engine power into maximum thrust. The 360-degree steering of the rudder propeller means that the full propulsion power is available for manoeuvring.

| Type | Input power [kW] | Input speed Z-Drive [min -1] | Input Speed L-Drive [min-1] | Propeller Ø [m] | Drive Variants | RT | SRP-D | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Z | L | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SRP 130 R | 330 | 1800 / 2000 | 1.00 | S | O | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SRP 190 R | 490 | 1800 | 1800 | 1.40 | S | O | O | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SRP 210 R | 560 | 1200 | 1.45 | S | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SRP 260 R | 880 | 1200 | 1200 | 1.65 | O | S | O | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SRP 340 R | 1300 | 1000 / 1200 | 2.10 | S | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SRP 380 R | 1500 | 1000 / 1200 | 750 | 2.20 | S | O | O | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SRP 460 R | 2450 | 750 | 2.60 | S | O | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SRP 610 R | 3500 | 750 | 3.20 | S | O | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SRP 700 R | 4000 | 750 | 3.60 | S | O | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SRP 750 R | 5000 | 750 | 3.80 | S | O | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

S = Standard, O = Option The above information is for guidance only. They do not apply to ice-classified ships. The final choice of propulsion unit depends on the actual operational profile of the vessel and is determined by SCHOTTEL. The ratings given are based on experience in the typical areas of operation of the respective vessel types. If you cannot identify your application in the “Typical applications” section or if you have a vessel with a special area of application, SCHOTTEL will be happy to determine the most suitable propulsion unit for you.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Type | Input power [kW] | Input speed Z-Drive [min -1] | Input Speed L-Drive [min-1] | Propeller Ø [m] | Drive Variants | RT | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Z | L | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SRP 190 RT | 490 | 1800 | 1800 | 1.40 | S | O | O | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SRP 260 RT | 880 | 1200 | 1200 | 1.65 | O | S | O | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SRP 460 RT | 2450 | 750 | 2.60 | S | O | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SRT 610 RT | 3500 | 750 | 3.20 | S | O | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

S = Standard, O = Option The above information is for guidance only. They do not apply to ice-classified ships. The final choice of propulsion unit depends on the actual operational profile of the vessel and is determined by SCHOTTEL. The ratings given are based on experience in the typical areas of operation of the respective vessel types. If you cannot identify your application in the “Typical applications” section or if you have a vessel with a special area of application, SCHOTTEL will be happy to determine the most suitable propulsion unit for you.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

In addition to developing new products and services, SCHOTTEL works continuously to optimize existing systems. Special features ensure that customers worldwide benefit from state-of-the-art solutions.

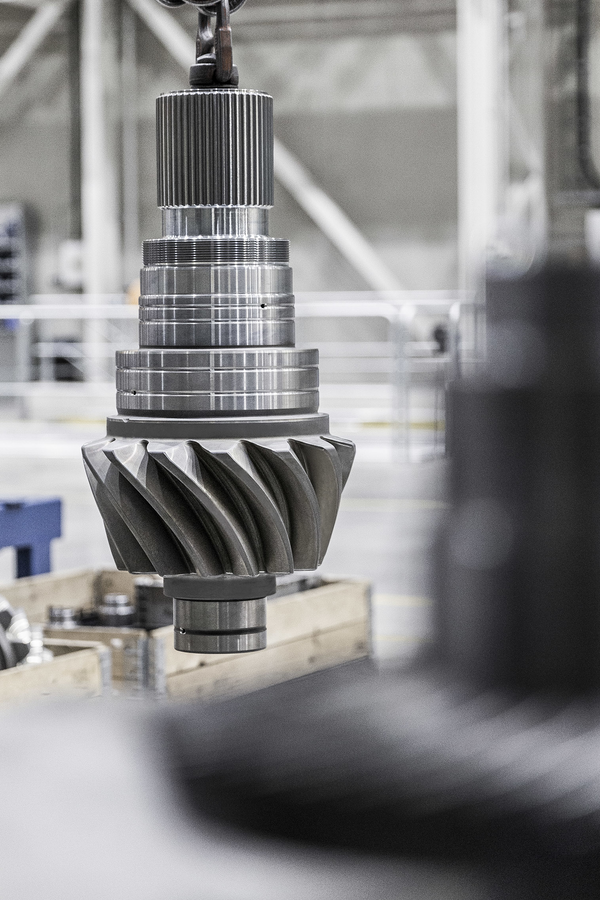

SCHOTTEL’s self-developed High Torque Gear (HTG) extends the service life of the gearbox, resulting in significant performance and safety gains. State-of-the-art milling and calculation methods are used to achieve shapes that enable a highly efficient, robust and safe gearbox with ideal gear geometry.

The HTG allows for example up to 15 percent more drive torque to be applied with the same bevel gear dimensions and in compliance with the same safety requirements of the classification societies.

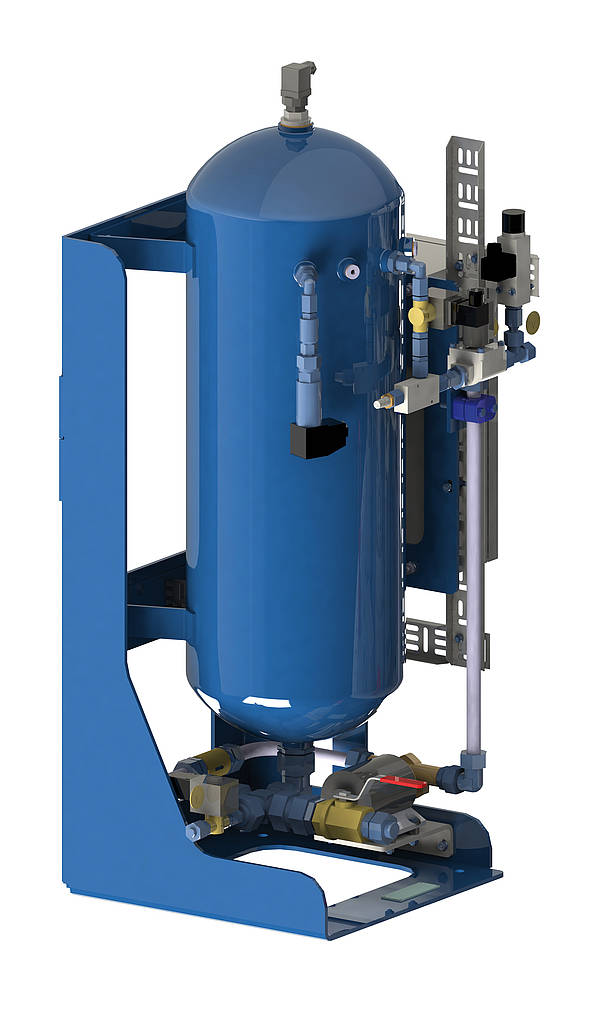

SCHOTTEL LeaCon is a sealing system certified by DNV which offers safe and reliable protection against contamination of the seawater by operating materials. Separate seals to the seawater and to the gearbox side ensure that both incoming seawater and escaping gear oil are collected in an intermediate chamber (LeaCon chamber). This effectively prevents water from entering the gearbox and, above all, oil from escaping into the seawater. With the connected vacuum system, the leakage fluid is automatically collected in a compact tank in the engine room.

In addition to the leakage-free sealing against seawater, the LeaCon system is used to monitor the condition of the seals. It registers the amount of leakage collected and continuously checks the condition of the seals. This means that operational wear can be detected at an early stage and unscheduled maintenance can be avoided.

SCHOTTEL propulsion units equipped with the patented LeaCon sealing system comply with the VGP regulations of the US-American Environmental Protection Agency (EPA). There is no need to use bio oils (EAL).

The German propulsion expert has set new standards for corrosion protection with the patented SCHOTTEL ProAnode: By moving the anodes from the outer surface to the outer cross-section of the nozzle, they are protected more effectively thus providing longer protection for the propulsion unit. There are also additional operational benefits, such as less flow disruption, resulting in fuel savings and lower operating costs.

To prevent the anodes from being knocked off by flotsam, ice or minor ground contact, they have been removed from the outer surface and integrated into the outer cross-section of the nozzle. Depending on their diameter and the anode material, these anodes can be integrated into the nozzle, allowing cathodic corrosion protection for up to five years. This means that fewer additional anodes are required on the hull or on other drive parts.

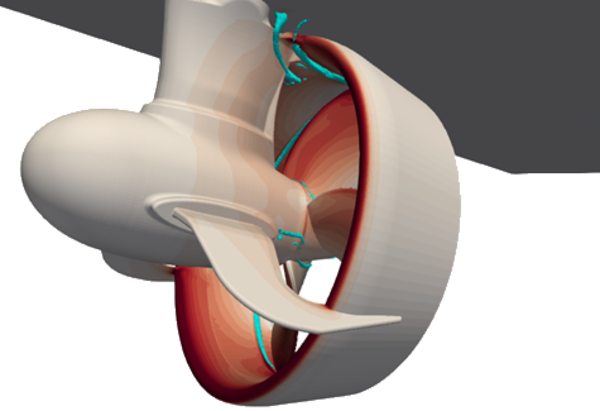

High-performance nozzles from SCHOTTEL are used in various types of vessels and applications to boost the propeller’s thrust force. Based on decades of propulsion expertise, SCHOTTEL VarioDuct (SDV) and SCHOTTEL CruiseDuct (SDC) feature impressively high outputs during free sailing and excellent bollard pull values. Part of this is the state-of-the-art technologies used to ensure the high performance characteristics of the nozzles.

The new nozzles are equipped with the exclusive ProAnode technology from SCHOTTEL as standard.

The SDV45 combines proven higher efficiency during free sailing with excellent bollard pull values. In conjunction with optimally designed propeller geometries, the nozzle is able to fully utilize the outstanding performance values. Assuming the same propulsion power, the bollard pull is higher than the thrust of previous nozzles, while efficiency is significantly enhanced in the medium and higher speed range. This makes a major contribution to fuel savings.

The SDV45 is suitable for use in a wide range of operation profiles.

The SDC40 sets standards in terms of compact design and free sailing efficiency, thus also reducing operating costs compared to nozzles from other manufacturers. The high-performance nozzle is also characterized by optimally designed propeller geometries and outstanding performance features.

The nozzle has a particularly small outer diameter. This enables it to be optimally adapted to a wide range of ship designs and applications. At the same time, the high-performance nozzle is also suitable for conversions and upgrades with limited installation space. The SDC40 excels with the highest free sailing efficiency in transit at higher speeds. In addition, a higher maximum speed can be achieved.

Further nozzles are available on a project-specific basis.