Efficient, low cavitation, streamlined – the SCHOTTEL TwinPropeller is the ideal propulsion solution for vessels or applications with limited installation space, draught or propeller clearance. Based on the principle of the proven SRP, the STP ensures combined thrust and 360-degree manoeuvring power with its two co-rotating propellers. Distributing the load over two propellers boosts the propulsion system’s efficiency and noise and vibration levels underwater and on board are reduced to a minimum.

The two co-rotating propeller design increases the propulsion system’s efficiency and reduces fuel consumption compared to single propeller systems. The load distribution minimizes the risk of cavitation and increases the clearance – the result: higher propulsion efficiency and lower noise levels.

| Type | Input power [kW] | Input speed Z-Drive [min -1] | Input Speed L-Drive [min-1] | Propeller Ø [m] | Drive Variants | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | Z | L | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| STP 100 | 190 | 200 | 225 | 1800 / 2300 | 0.75 | S | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| STP 150 | 330 | 360 | 400 | 1800 / 2100 | 1300 | 1.05 | S | O | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| STP 210 | 490 | 560 | 630 | 1200 | 1.30 | S | O | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| STP 260 | 770 | 820 | 920 | 1000 / 1200 / 1500 / 1800 | 1200 | 1.65 | S | O | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| STP 340 | 1090 | 1170 | 1250 | 1400 | 750 / 900 / 1000 / 1200 / 1600 / 1800 | 750 | 2.00 | S | O | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| STP 460 | 1830 | 1960 | 2100 | 2350 | 750 / 900 / 1000 / 1200 / 1600 / 1800 | 2.50 | S | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| STP 560 | 2200 | 2350 | 2500 | 3200 | 2.65 | S | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

S = Standard, O = Option The above information is for guidance only. They do not apply to ice-classified ships. The final choice of propulsion unit depends on the actual operational profile of the vessel and is determined by SCHOTTEL. The ratings given are based on experience in the typical areas of operation of the respective vessel types. If you cannot identify your application in the “Typical applications” section or if you have a vessel with a special area of application, SCHOTTEL will be happy to determine the most suitable propulsion unit for you.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

In addition to developing new products and services, SCHOTTEL works continuously to optimize existing systems. Special features ensure that customers worldwide benefit from state-of-the-art solutions.

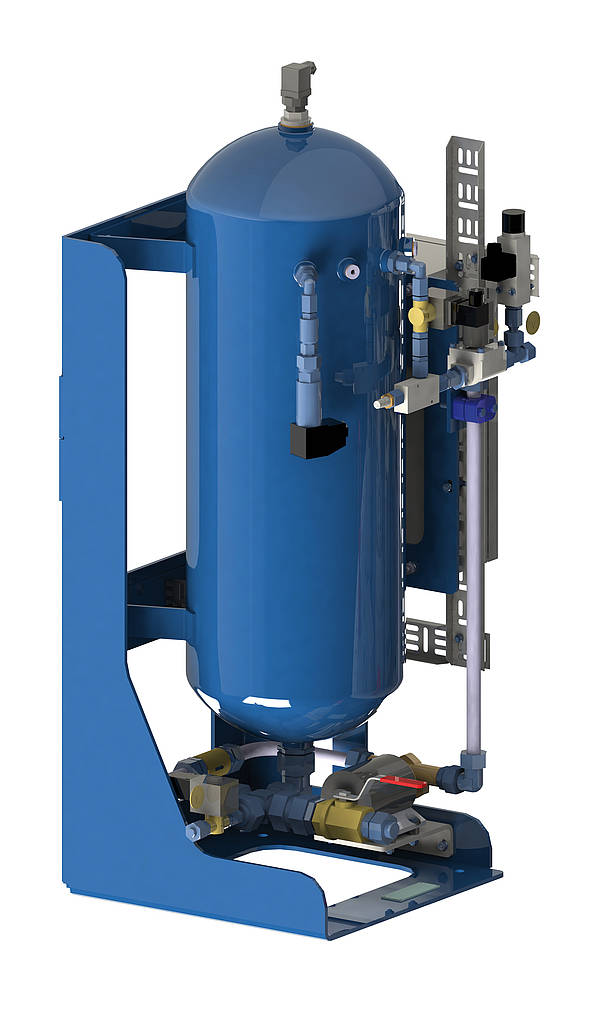

SCHOTTEL LeaCon is a sealing system certified by DNV which offers safe and reliable protection against contamination of the seawater by operating materials. Separate seals to the seawater and to the gearbox side ensure that both incoming seawater and escaping gear oil are collected in an intermediate chamber (LeaCon chamber). This effectively prevents water from entering the gearbox and, above all, oil from escaping into the seawater. With the connected vacuum system, the leakage fluid is automatically collected in a compact tank in the engine room.

In addition to the leakage-free sealing against seawater, the LeaCon system is used to monitor the condition of the seals. It registers the amount of leakage collected and continuously checks the condition of the seals. This means that operational wear can be detected at an early stage and unscheduled maintenance can be avoided.

SCHOTTEL propulsion units equipped with the LeaCon sealing system comply with the VGP regulations of the US-American Environmental Protection Agency (EPA). There is no need to use bio oils (EAL).

DuroVario allows SCHOTTEL to offer fully integrated clutches, optimally adapted to the propulsion properties of the respective propulsion system. Customers benefit from an above-average service life, which goes hand in hand with high service and spare parts availability. The compact and space-saving clutches also enable easier integration into a wide range of ship designs and straightforward installation thanks to plug-and-play setup.

Depending on the type of clutch, the engine power is transmitted either by a simple on/off function or a convenient slipping function. The SCHOTTEL portfolio has the perfect solution for any application – all from a single source.